Over the past few decades, electronics engineers have developed increasingly flexible, versatile and highly performing devices for a wide range of real-world applications. Some of their efforts have been aimed at creating smart and sensing textiles, which could be used to fabricate stretchy robotic systems, medical devices and wearable technologies.

Researchers at Jiangnan University recently introduced a new textile engineering approach to fabricate woven and soft actuators for health care technologies and robotic systems. Their proposed fabrication strategy, outlined in a paper in Cell Reports Physical Science, is both scalable and easily-designable, which could contribute to its future large-scale adoption.

“Conventional methods like 3D printing and elastomer casting did not quite meet the need for adaptability and comfort in soft robotics and wearable devices, particularly in terms of developing integrated devices that are not only flexible and functional but also low-cost, easily customizable and scalable,” Dr. Fengxin Sun, corresponding author of the paper, told Tech Xplore.

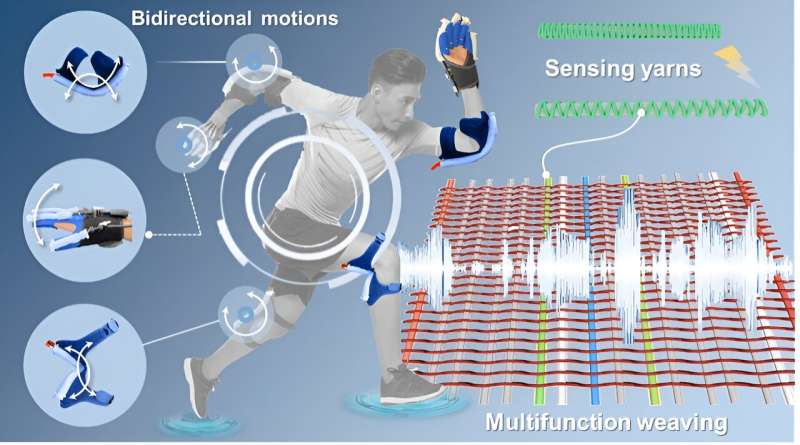

“Inspired by the ‘yarn-to-clothes’ manufacturing method, we utilized a two-system weaving technology to seamlessly integrate both sensing capabilities and actuation modes into soft robotic ‘garments.'”

The technology employed by Sun and his colleagues arranges warp and weft yarns (the two basic components used to transform threads into fabrics) into a clear planar layout while weaving them. This means that it enables the customization of woven actuators, which is attained by carefully programming the arrangement and composition of yarns.

“Our approach enables personalized morphing and real-time sensing feedback, making the woven actuators particularly effective for applications like rehabilitation wearables,” Dr. Sun said. “The fabrication of the sensing yarn is quite simple, resembling the creation of a braided hairstyle. Conductive yarns are braided in a helical pattern around stretchy core yarns using an industrial braiding machine, creating pathways for electrical current.”

When the yarn used to weave the actuators is stretched, the pathways through which electric current can flow are switched off, due to the separation of the conductive yarns’ helices. This change in structure in turn affects the electrical signals flowing through the yarn, thus enabling the detection of strain.

“The sensing yarns we developed are integrated directly into the fabric of our woven actuators,” Dr. Sun said. “Essentially, as the actuator moves, the resistance in the yarn changes, and this data can be used to understand how the actuator is performing.”

A unique characteristic of the sensing yarns produced using the team’s method is that they are fully woven into fabrics. This means that they do not add any weight, stiffness or bulkiness to textiles, allowing actuators to monitor their own movements without losing their flexibility and adaptability.

“Thanks to the two-system weaving technology, we can tailor woven pneumatic actuators to inflate only in our expected directions, effectively addressing the ‘balloon-like’ inflation problem faced by the soft robotic community,” Dr. Sun said.

“Moreover, our weaving strategy offers a flexible and scalable solution for fabricating multi-morphing soft actuators, such as those capable of bilateral bending, twisting and spiraling under a single air supply, by simply adjusting the yarn tension, density, and woven structure.”

The researchers demonstrated the feasibility of their yarn for developing bilateral bending actuators, which could be used as soft robotic grippers. These grippers could be used to mimic the movements of animals, for instance reproducing the extension of octopus tentacles to pull objects closer and grasp them.

“These actuators have also practical applications in wearable rehabilitation devices, where they can provide more precise and adaptive support to people with mobility challenges,” Dr. Sun said. “The ability to program these actuators to mimic natural human movements means they could be used in a wide range of assistive technologies, making them more effective and comfortable for users.”

In the future, the textile engineering approach introduced by this team of researchers could be used to manufacture a wide range of flexible components for medical devices and robotic systems. Dr. Sun and his colleagues plan to continue working towards the advancement of textile manufacturing for technological applications, devising other weaving and knitting strategies.

“We aim to develop textile actuators with improved output and versatile motions in a more controlled way,” Dr. Sun added. “We believe that refining the design of hierarchical textile structures will address key challenges faced by the soft robotics community, such as balancing flexibility and tenacity in soft actuators. This process could expand the potential application of textile-based soft robotics and make a greater impact on everyday life.”

More information:

Haoyun Li et al, Yarn-grouping weaving soft robotics with directional inflation, bilateral bending, and self-sensing for healthcare, Cell Reports Physical Science (2024). DOI: 10.1016/j.xcrp.2024.102137

© 2024 Science X Network

Citation:

Scalable woven actuators offer new possibilities for robotics and wearable devices (2024, August 20)

retrieved 23 August 2024

from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

link